Nike Grind: A legacy of innovation

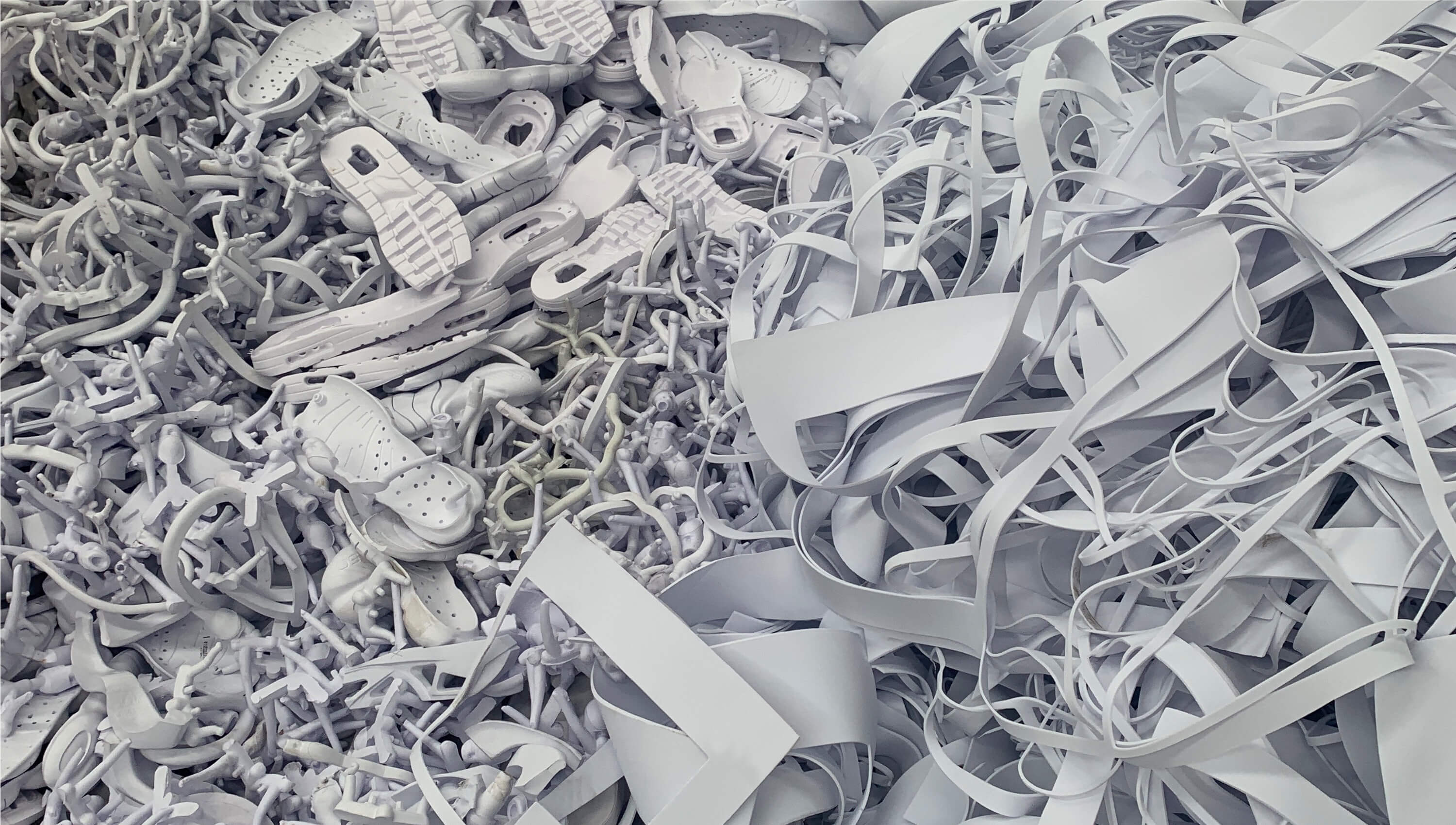

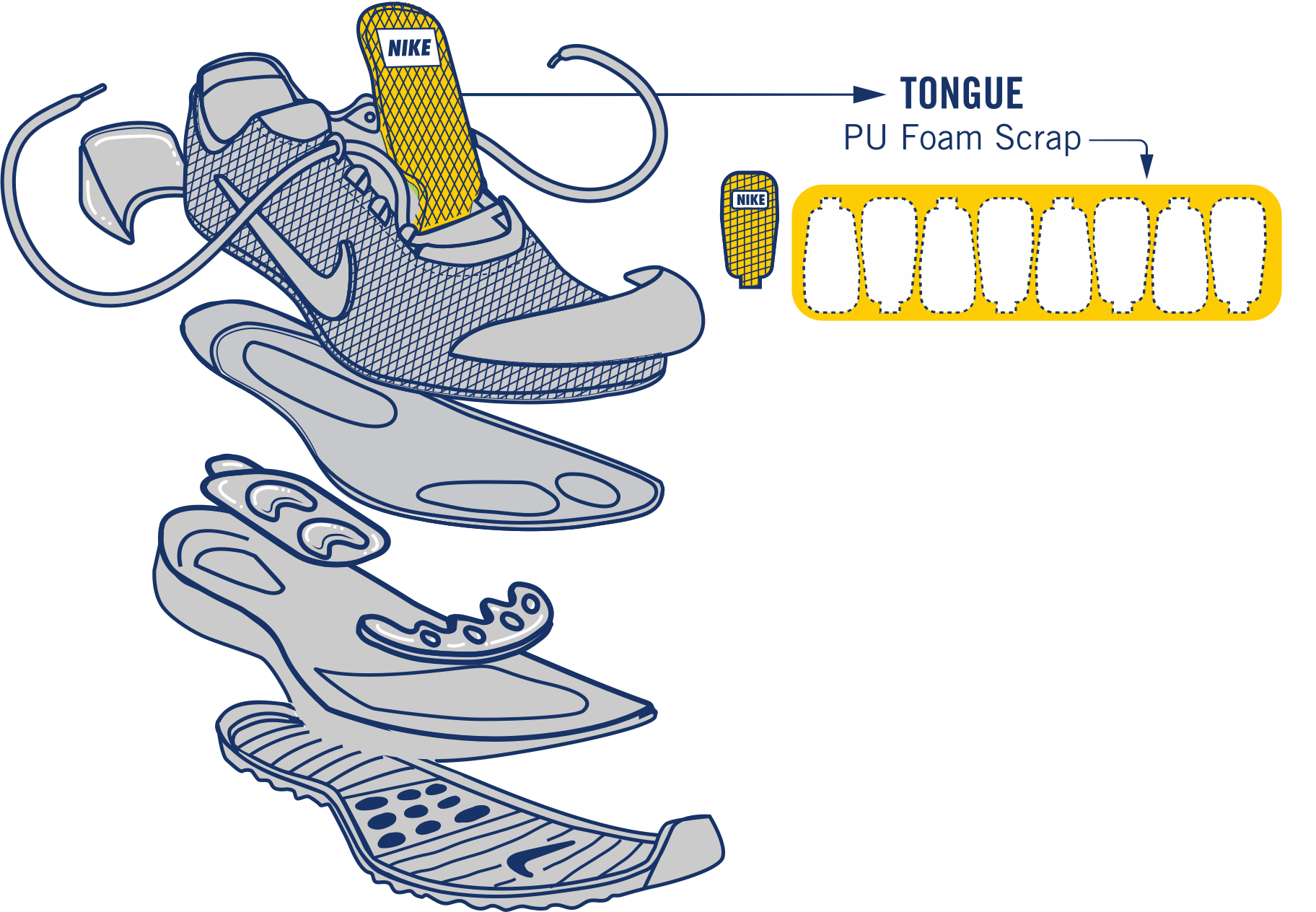

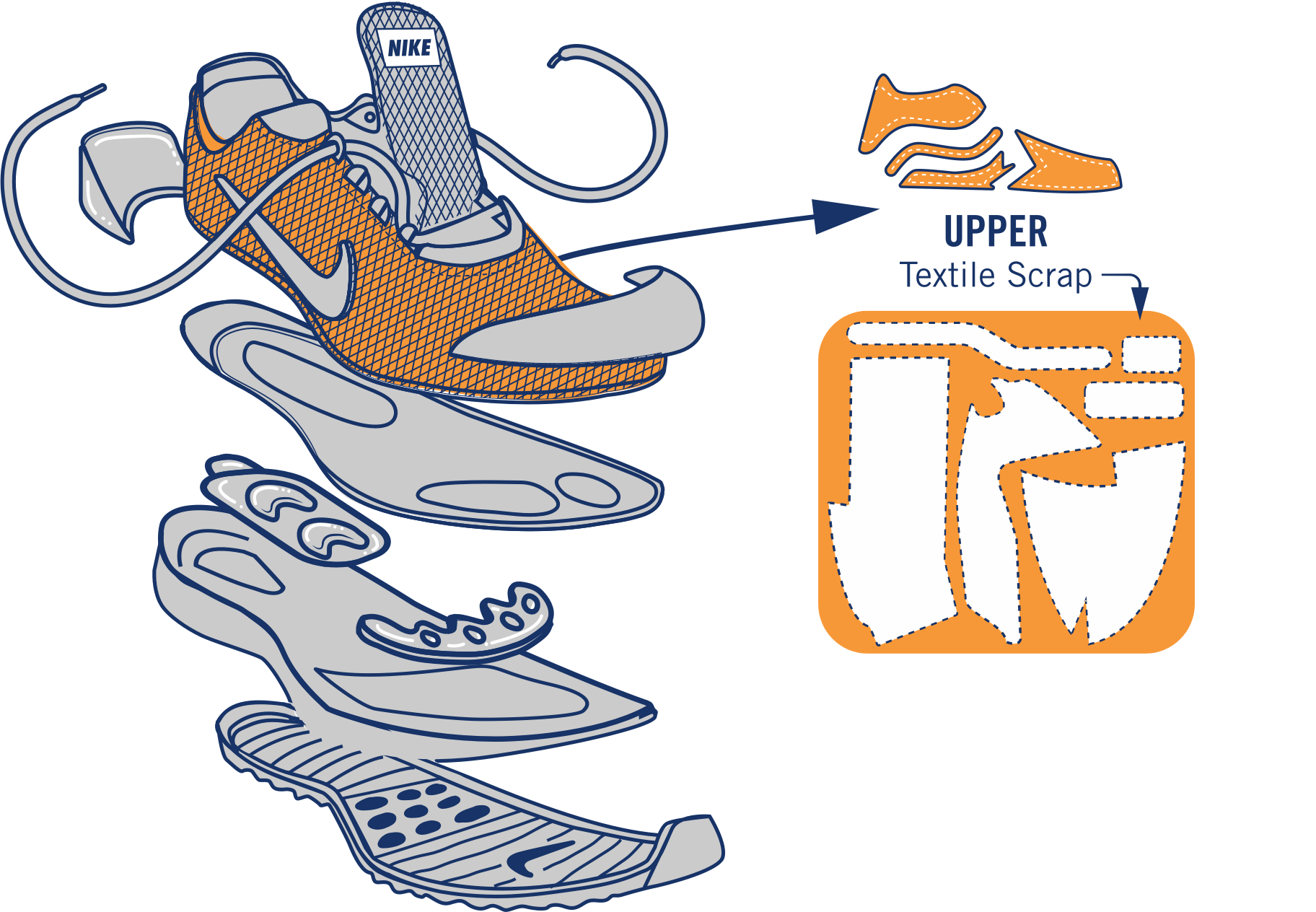

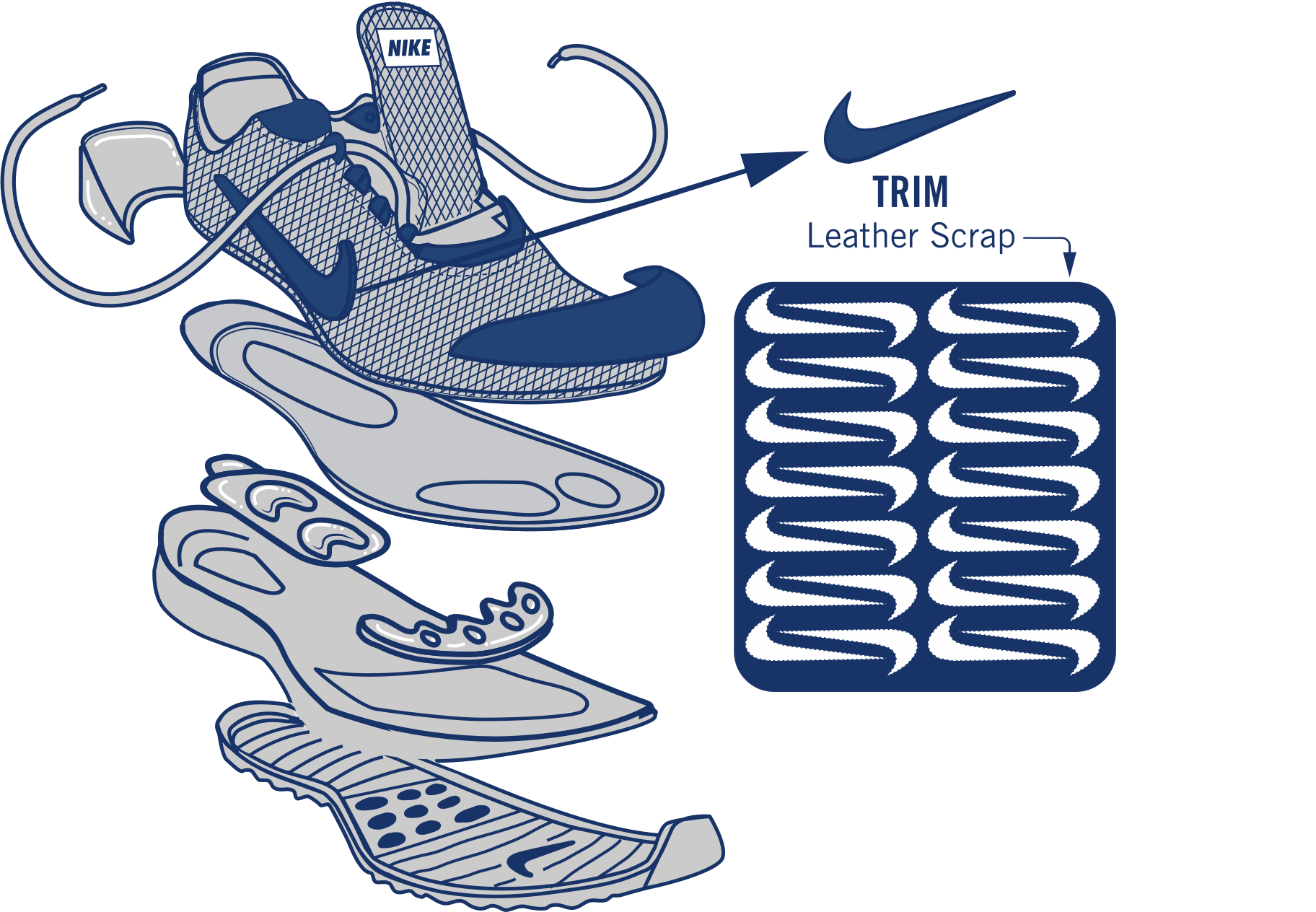

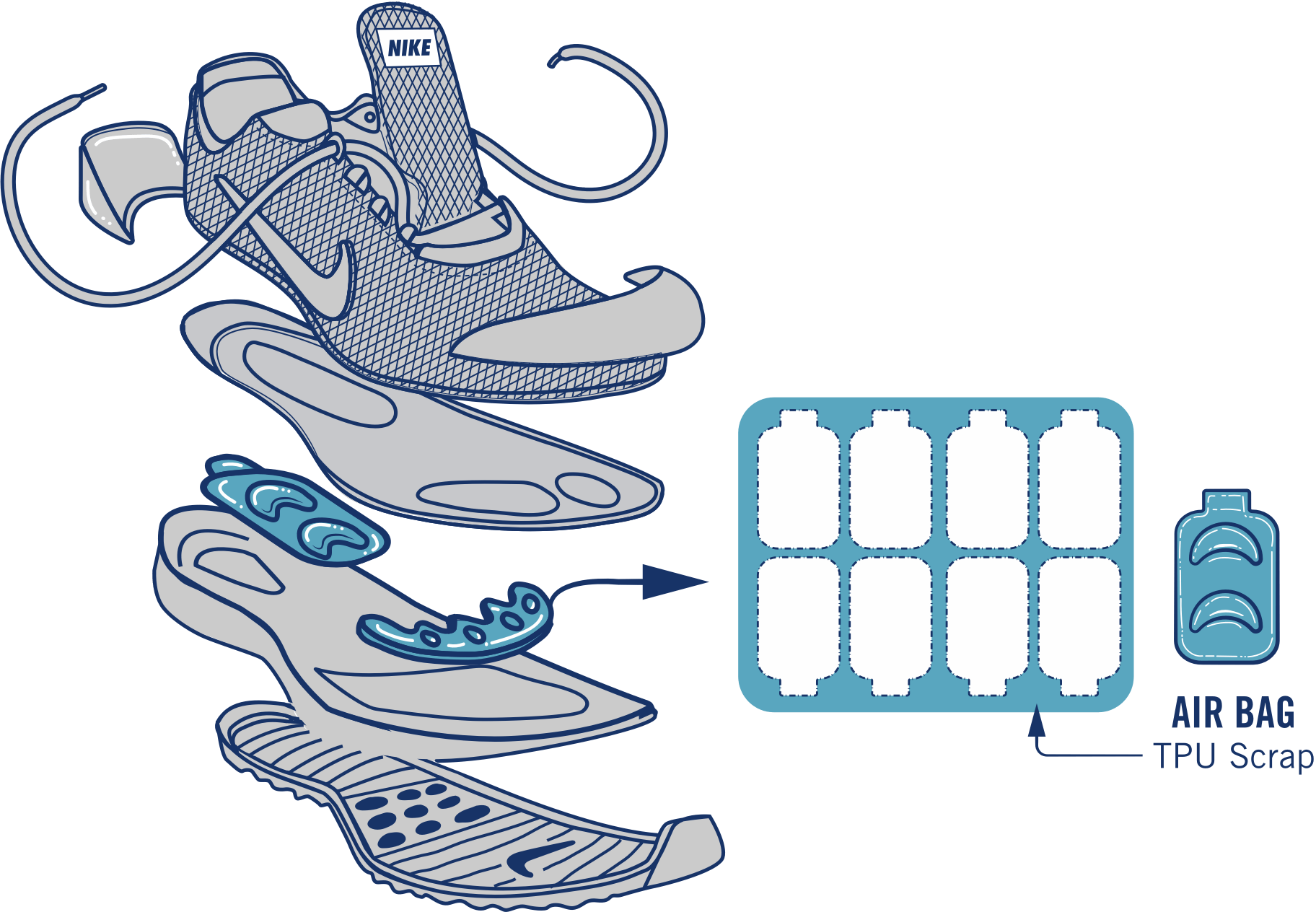

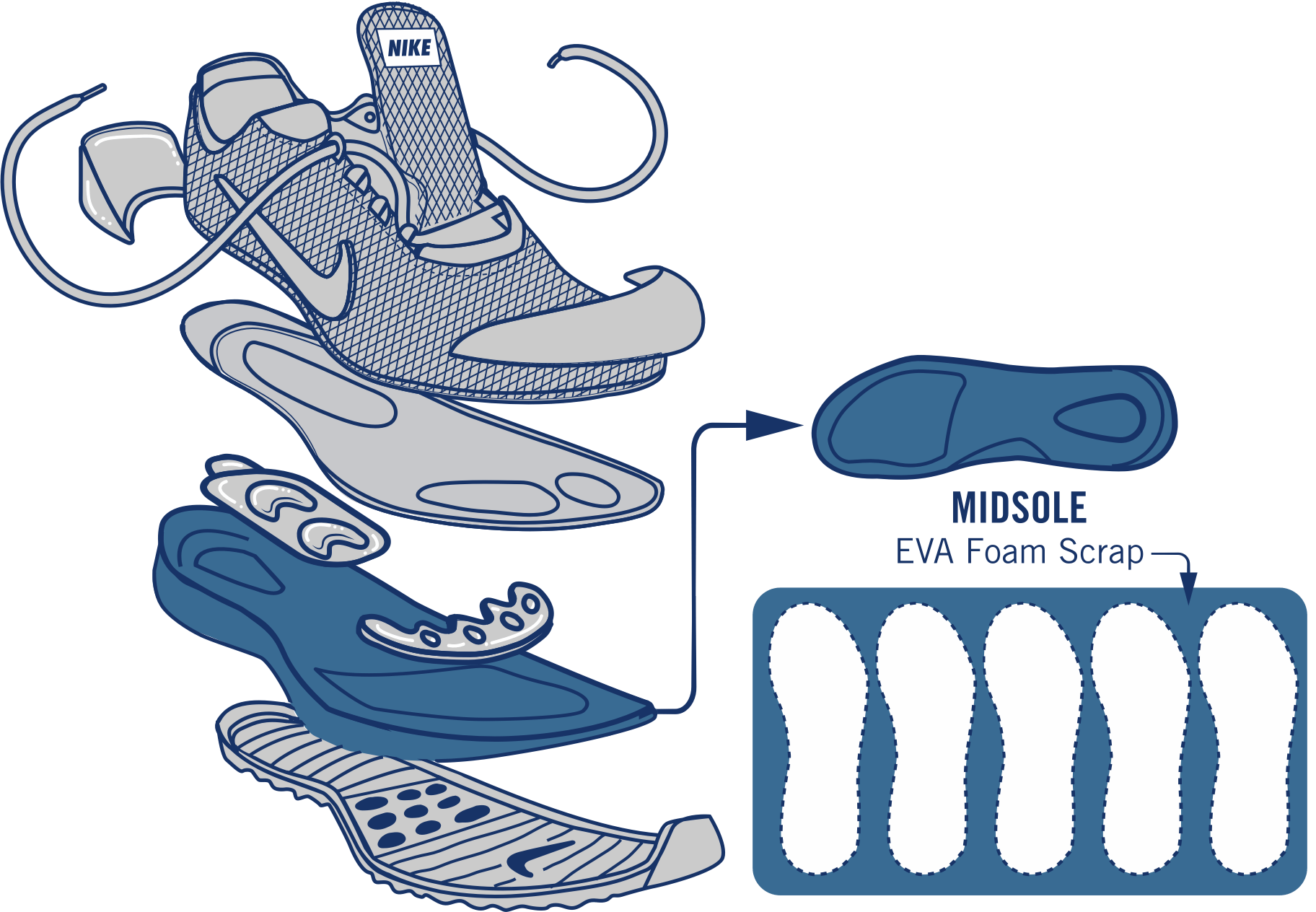

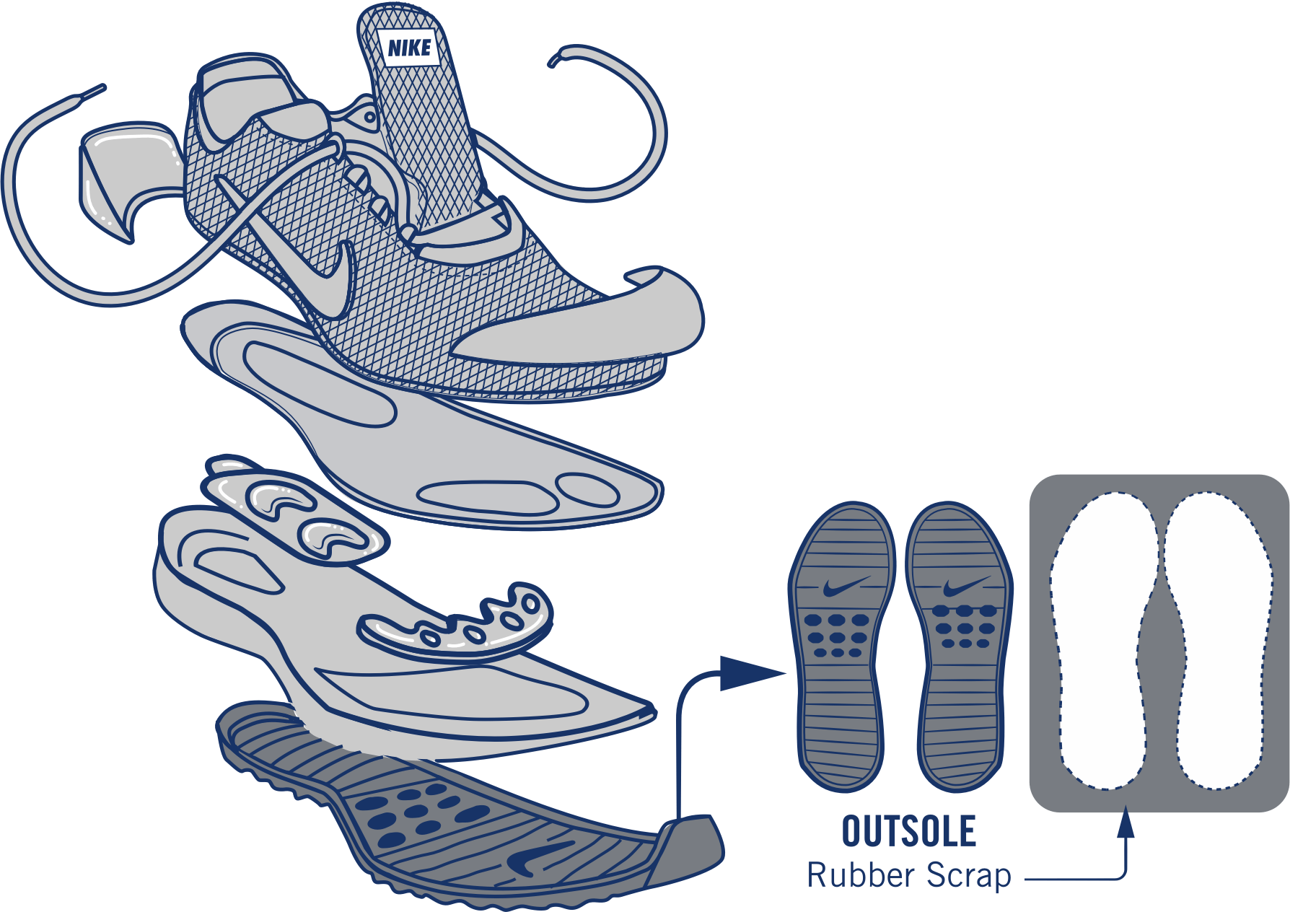

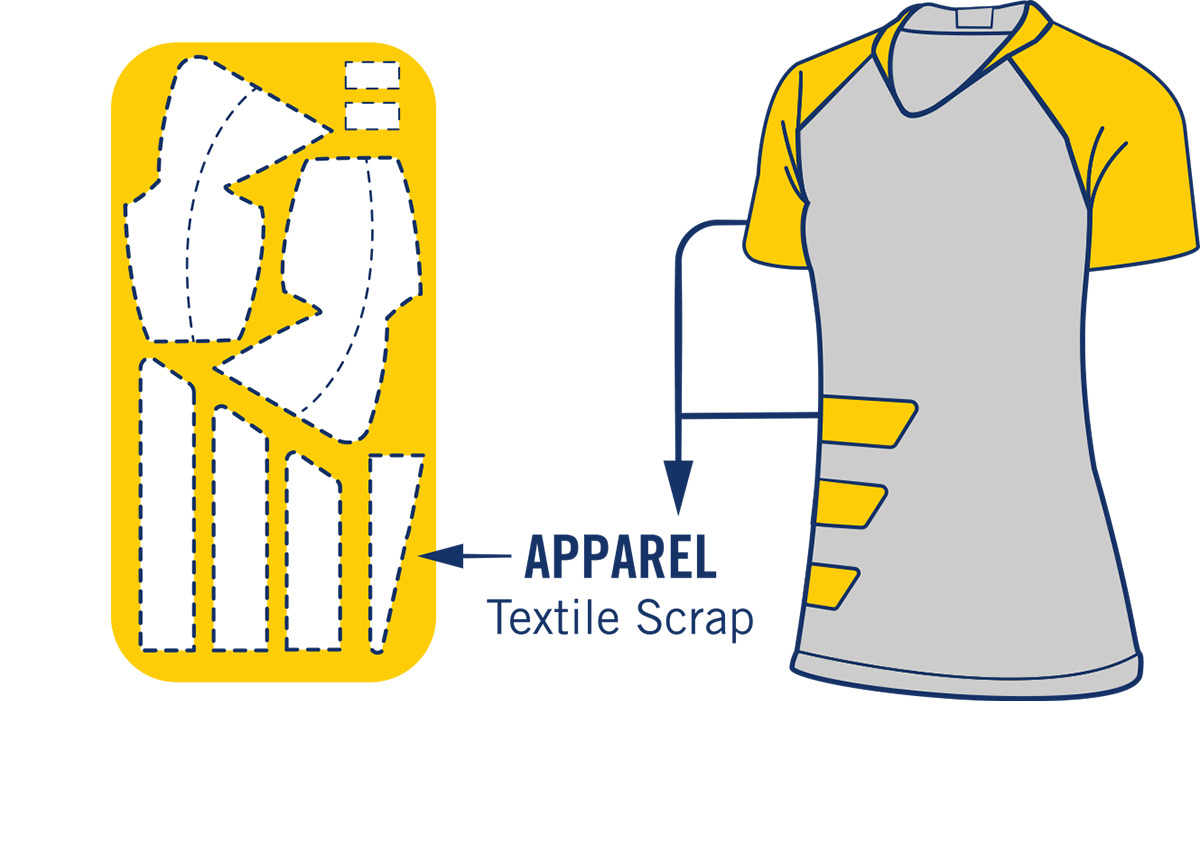

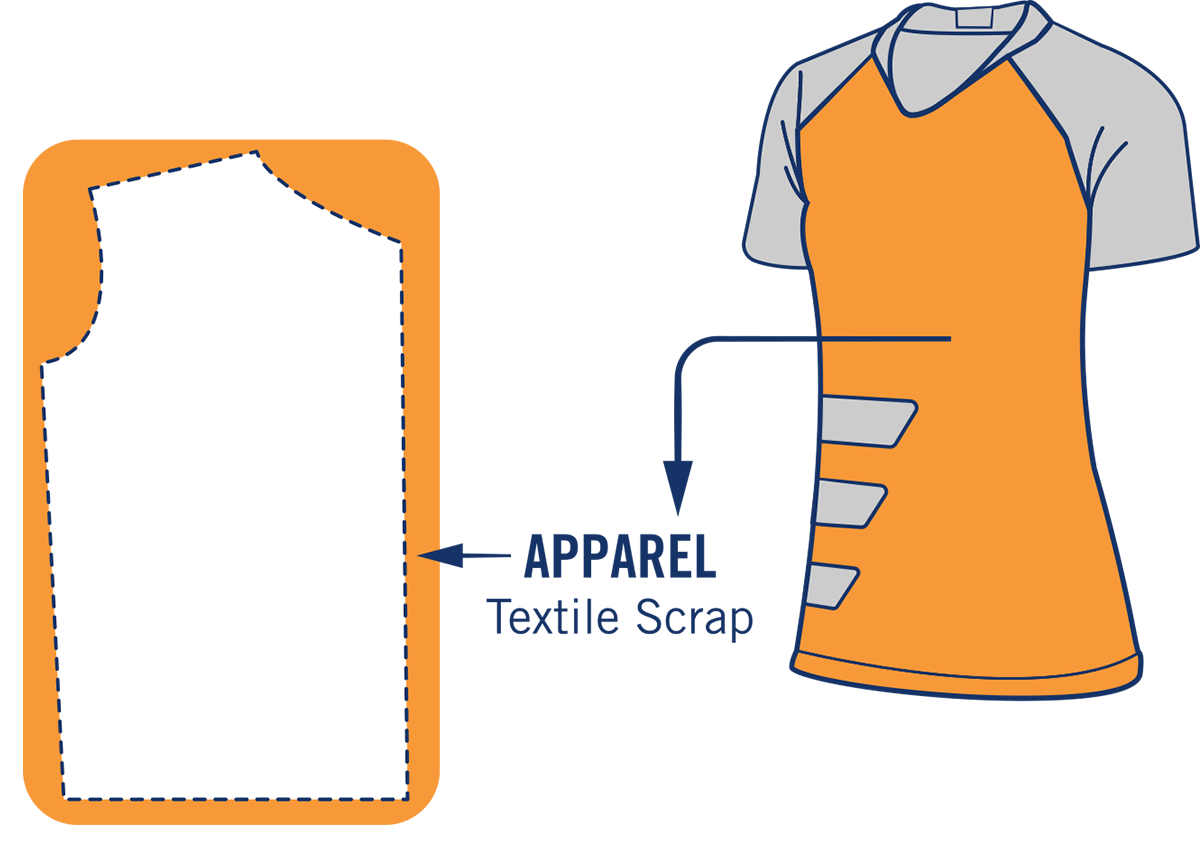

What began as a grassroots initiative in 1992 to repurpose shoes headed for landfills is now a global sustainability program that helps transform manufacturing scrap and end-of-life shoes into recycled Nike Grind materials. It’s all part of our vision for a circular future—one where the concept of waste no longer exists.