Nike Grind

30 years of

relentless innovation

relentless innovation

Our long-term vision: creating a continuous loop without waste.

Our long-term vision: creating a continuous loop without waste.

Learn more about Nike GrindFeatured stories and products

“Waste is simply excess material in the wrong person’s hands.”

“Waste is simply excess material in the wrong person’s hands.”

Peggy Reid, Circular Economy Director, Nike, Inc.

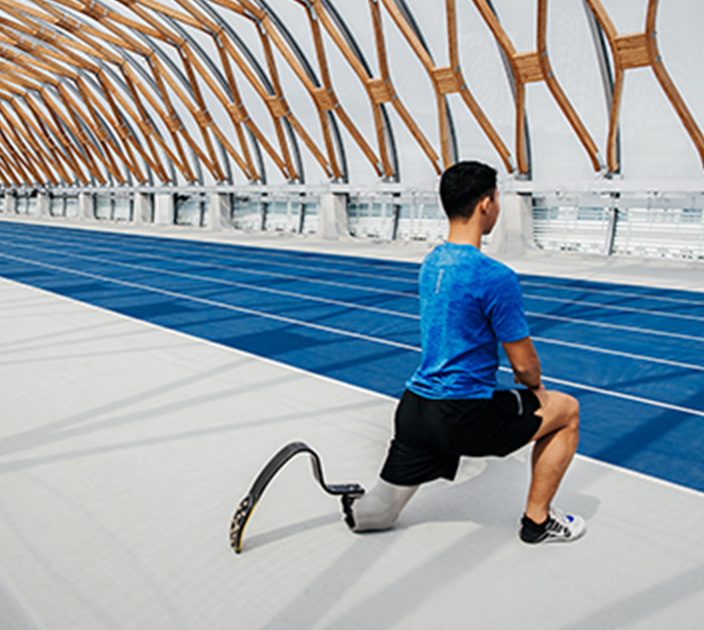

WINNING PRODUCTS. MADE BY INDUSTRY LEADERS.

Our innovative partners are using Nike Grind materials to make high-performance surfaces and products.

Together, we’re transforming waste into limitless potential.